3A Sampling Valves

Aseptic Sampling Valve S3

Designed for sampling medium viscosity products, with particles up to 3 mm in diameter, if fitted with PTFE membrane and 2mm when fitted with silicone or EPDM membrane

• Material:316L SS.

• Max temperature: 120ºC .

• Surface finish: Polish Ra≤0.8µm .

• Certifications: 3A.

• Material:316L SS.

• Max temperature: 120ºC .

• Surface finish: Polish Ra≤0.8µm .

• Certifications: 3A.

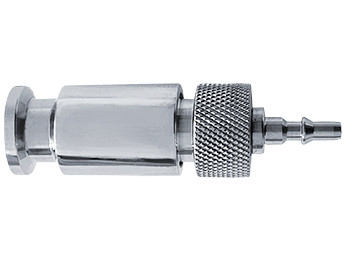

Aseptic Sampling Valve S3/2

Sanitary Sampling Valve with High Velocity, designed for continuous random sampling without interrupting production .

• Material:316L SS.

• Max temperature: 120ºC .

• Surface finish: Polish Ra≤0.8µm .

• Certifications: 3A.

• Material:316L SS.

• Max temperature: 120ºC .

• Surface finish: Polish Ra≤0.8µm .

• Certifications: 3A.

Aseptic Sampling Valve S3/4

S Series aseptic sampling Valves are designed for sampling low viscosity products, with particles below 8 mm in diameter,and offer flexible connection types, including welding clamping, and hose connections, ensuring conntinuous random sampling without interrupting production

• Material: 316L SS.

• Sterilization Temperature:- 20°C ... 120°C .

• Surface Treatment: Inner surface EP Ra ≤ 0,5µm.

• Certifations:3A.

• Material: 316L SS.

• Sterilization Temperature:- 20°C ... 120°C .

• Surface Treatment: Inner surface EP Ra ≤ 0,5µm.

• Certifations:3A.

Angle sampling Valve CS2

Sanitary Sampling Valve with Sillicone Seat, designed for easy cleaning and assemply.

• Material:316L SS.

• Max temperature: 140ºC .

• Surface finish: Polish Ra≤0.8µm .

• Certifications: 3A.

• Material:316L SS.

• Max temperature: 140ºC .

• Surface finish: Polish Ra≤0.8µm .

• Certifications: 3A.

Straight Through CS4

Sanitary Sampling Valve with Sillicone Seat, designed for easy cleaning and assemply.

• Material:316L SS.

• Max temperature: 140ºC .

• Surface finish: Polish Ra≤0.8µm .

• Certifications: 3A.

• Material:316L SS.

• Max temperature: 140ºC .

• Surface finish: Polish Ra≤0.8µm .

• Certifications: 3A.

SOLUTIONS AND ATEX CLASSIFICATION

Atex is the conventional name of 94/9/CE policy of European Union for regulation of equipment for Atex zone. The Policy became effective 1st March 1996 and became binding 1st July 2003 for all European countries and sets Atex certification for all products marketed in the European Union, apart from production place and laws in force, if installed in Atex environments. Since Atex policy came in force, CO.RA. attuned its own products to satisfy these requirements demanded by European Policy to chemical and pharmaceutical industries. The firm R & D activity, process validation and all concerning the warranty of a complete service to offer its customers, employed CO.RA. staff in a specific research to manufacture “Made in Italy” Atex gaskets for Sole Valve®, Rotary Valve®, Double Valve®.